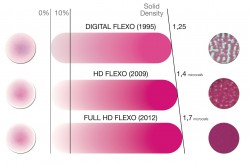

| One major advantage of the new technology is the digital control of the shape of the molded dots. With it, users can produce printing plates and sleeves that combine the advantages of HD Flexo and the ability to achieve high optical density with the stability of a flat form of flexographic printing, in one, fully digitally controlled trial. |

Until now the combination of smooth highlight printing and gravure-like solid ink densities for flexible packaging remained difficult. Nowadays Esko significantly improved flexo platemaking with its HD Flexo technology. Since its premiere during last drupa, HD Flexo was modernized and perfected for flexible packaging manufacturers. The success of the latest version is proved by more than twenty installations at flexo tradeshops and converters worldwide.

”With Full HD Flexo, Esko once more raises the standard. Esko flexo customers are asking for the combination of the benefits of HD Flexo together with a gravure-like ink laydown and a fully digitally controlled platemaking workflow. This is what Full HD Flexo brings and it moves flexo to an unseen level of quality and consistency with no need for compromises. Our unique, patented technology stretches the possibilities of flexo printing, allowing it to perfectly match gravure and offset quality for flexible packaging,” explains Jürgen Andresen, Esko Vice President, Flexo Business.

No Need for compromises

HD Flexo quickly has set new standards thanks to the fine highlights in the critical range for flexo from 1-10 percent, transitions to zero, sharp text and brilliant image details it produces. Full HD Flexo adds gravure-like solid ink laydown of the correct solid density, along with vibrant brand colors, supreme platemaking consistency and the only fully digitally controlled platemaking workflow available in industry. The unique Full HD Flexo dot shape delivers a superior flexo plate suitable for the highlight, shadow and solid areas of a print job. “We went beyond the binary discussion of flat top or round top dots, and created the best possible combination of print dot structures on one plate. This enables to differentiate the ink laydown on the substrate for different parts of the artwork on one single plate. This is a giant step forward for flexible packaging converters as the result is high quality flexible packaging that stands out. In addition, users report better performance of the flexo plate on the press for print consistency and printing speeds," explained Jan Buchweitz, Esko Senior Product Manager Digital Flexo.

|

| Full HD Flexo technology allows printing of fine highlights in the critical range for flexo from 1-10 percent, transitions to zero, clear fonts and graphic details exposed by using rotogravure inks constant density, vivid colors and repeatable manufacturing process printing plates. |

Flexo miracle

The Full HD Flexo technology combines high resolution imaging at 4000ppi (HD Flexo imaging and screening technology) with digitally controlled main exposure inside the CDI. The digital Inline UV2 main exposure through a LED-array delivers a UV power density high enough to gain full control over the polymerization process during main exposure. Digital control of all settings of the process provides repeatable production of printing plates, long-term stability and quality that exceeds the capabilities of the standard UV exposure. Full HD Flexo works with all popular digital flexo plates and sleeves (including DuPont, Flint, MacDermid, Asahi and others), giving users the freedom to choose whatever plate best fits their business needs. Currently Esko is planning on starting a certification program for the clients, distributors and partners, based on the standards applied in HD Flexo (including inspection of five samples from jobs that have been printed consistently). Full HD Flexo for flexible packaging is available worldwide. Existing customers can upgrade their software, workflow and CDI equipment to Full HD Flexo. The Full HD Flexo application support for labels and corrugated printing will be available later this year

Milestone

Over 20 customers worldwide are running production using the new Full HD Flexo technology today. An Austrian specialist packaging prepress as well as plate production for flexo printing and plate assembly for corrugated board, Glatz Klischee is particularly positive about Full HD Flexo. "We’ve achieved a quantum leap forward in flexo printing. In the first printing tests using the new Full HD Flexo plates, we had the ‘luxury problem’ of solid densities over a density of 2.0,” reported Holger Stier, Technology Manager at Glatz Klischee. “This was completely unexpected with the fine anilox rollers used. The tests proved that the option of combining flat top and round top dots technology on one printing form offers previously unheard opportunities in high-quality flexo printing.” On the other hand one of the largest tradeshops offering the most flexo plate services in Latin America, Brazilian company Clicherlux, speaks highly of the tonal changes. “I can say we have reached the quality of offset printing, with no gain, or bump-up curves. Full HD Flexo is really producing the full tonal range from highlights to shadows. An Esko CDI digital flexo imager along with Full HD Flexo is the best combination in the market,” commented Luciano Trombeta, Gerente Técnico. “We’re getting the flat top dots we wanted in the shadows, along with great screens in the highlights.”

| « previous | next » | « « back |

drukuj

drukuj

It protects, expands the expiry date, persuades. Packaging. Influenced by an intriguing design, often we decide to buy something on impulse, that wasn’t to be found on our shopping list. We are tempted by their beautiful forms, intrigued by embossed printing made by innovative, cutting-edge technology and by the use of unusual materials.